This is my sandbox....

I present to you my best posts, hope to trigger your inspiration!

Want more, want to discuss? ....then let's meet!

J.B. van Doesburg

Me, lecturer at HR

J.B. van Doesburg

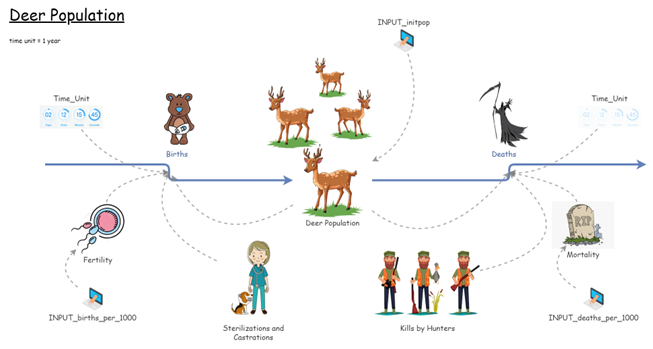

Investigations into wild deer stock control using System Dynamics Modelling

To control the life stock, local government has the responsibility to control the size of the herds that are grazing our national nature reserves. The preferred solution of our policymakers is to issue hunting permits. This will eventually result in a reduction of the life stock as well as provide income to the local government. The income of course only balances costs made by the government to provide the service (for hunting).

An alternative solution however does exist. This more animal friendly and more sustainable solution is realized when birth control is exercised. Hunters in employment of the government now must capture the buck of the herd (primal mail deer). Then a vet will perform a castration on a single deer resulting in birth control of the complete herd! A solution that prevents deer gestation in up to 20 deer that make up the herd. This solution does require some investment of the taxpayer's money; but do we not all want to go back to nature?

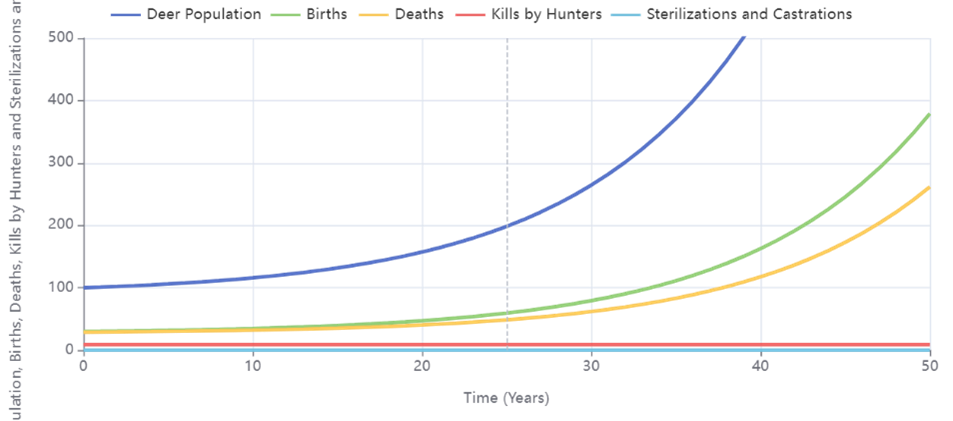

Using System Dynamic modelling an analytical tool has been created to investigate the effectiveness of both solutions. The image above shows the System Dynamics Model with stocks, flows and data lines. One of the many resulting graphs generated is presented below. Using the model, it can be shown that in a 50-year period life stock indeed can be controlled by either killing or by the more animal friendly principle of medical intervention.

Me, entrepreneur

TopBob Engineering

2015-2022

J.B. van Doesburg